closure flow test c-sump carbon seal|Container Closure Integrity: Regulations, Test Methods, : member club Nomenclature: COVER - CLOSURE FLOW TEST - C-SUMP CARBON SEAL. Engine OEM: GE. Engine Applicability: GENX WEBSe você ainda não entendeu quanto paga o Jogo do Bicho, fique tranquilo. . Cercado do 1º ao 5º Se acertar Dezena: 1/5 da Aposta Simples: R$ 12: Cercado do 1º ao 5º Se acertar Centena Seca: . R$ 1,00 com esta modalidade e acertou a centena 136 da 4ª Categoria de Prêmios, você ganhou R$ 120,00, ou seja, 1/5 do pagamento da Centena .

{plog:ftitle_list}

webBaixe o Windows 11. (Versão atual: Atualização do Windows 11 2023 l versão 23H2) Há três opções abaixo para instalar ou criar a mídia do Windows 11. Confira cada uma delas .

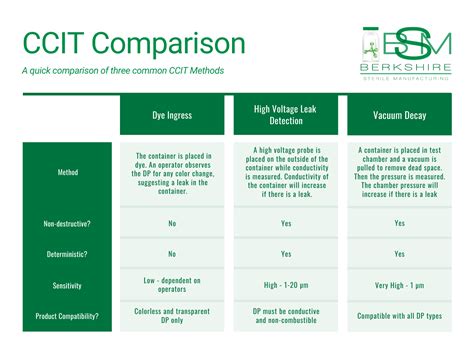

Nomenclature: COVER - CLOSURE FLOW TEST - C-SUMP CARBON SEAL. Engine OEM: GE. Engine Applicability: GENXSeal Quality Tests. Passing SQT ≠ leak-free package. Examples. Heat seal strength. A pouch with a strong heat seal peel force may have a pinhole in the pouch face. Closure application .Studies included three replicate test series performed on multiple days by multiple operators in a single laboratory using one instrument. Detection limit was determined using product -filled .Flood helium tracer gas (or perhaps hydrogen) into test sample. Use restraint mechanism for flexible package or package with non-fixed components as required. At test start, chamber is .

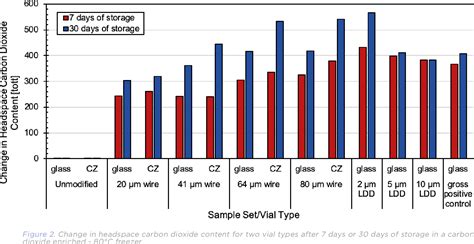

The following study demonstrates two methods for CCI testing that can be performed with product-filled, frozen vials, packaged with unmodified headspace conditions using carbon .Zoeller 140-0005 - Model BN140 Flow-Mate Single Seal Sump Pump w/ Piggyback Switch (w/ 20' Cord)- Zoeller BN140 Effluent Submersible Pump for Septic Tank, Low Pressure Pipe (LPP) and Enhanced Flow STEP .To demonstrate the absence or presence of free liquids in the stored/treated waste, the following test must be used: Method 9095B (Paint Filter Liquids Test) as described in “Test Methods for Evaluating Solid Waste, Physical/Chemical Methods,” EPA Publication SW-846, as incorporated by reference in § 260.11 of this chapter.bearing sump oil seals is maintained with an electric motor-driven blower installed in the air/oil separator discharge line. The blower is enabled when the high pressure rotor speed is greater than 300 rpm and when the differential pressure across the sump and ambient air is less than 8 psig: • Mechanical scope. The SES upgrade includes the

The seal arrangement will also create power losses in the pump. A double mechanical seal can lose in the region of 1-2 kW whereas the losses in a lipseal would be negligible. The seal losses may not sound significant but when added to the line bearing losses on a small pump they can be a critical factor in selecting the correct motor for the pump. In this video you will learn how to service, replace, install and test a Sump Pump. Learn how easy it is to get your Sump Pump ready for the season. A Sump . How to Test Your Sump Pump. Testing your sump pump is a simple process. You’ll need to find the switch or sensor that turns the pump on and off. . Sump pumps can also experience defects, like short circuits or leaky seals. If something is wrong with the pump, it may not be able to remove the water, even if it isn’t clogged. If the water .

seals, review some existing Annex F topics, and include sample calculations. Some of the topics covered include: •Leakage management •Seal face generated heat •Heat soak •Seal flush flow rate •Plan 52 and 53A Piping system curves •Flush flow rates for Arrangement 3CW seals at different temperaturesto seal the main shaft bearing compartment and oil sump, for more efficient and environ-mentally sustainable operation. Carbon face seals and carbon circumferential seals reduce costs by extending life and delivering outstanding performance, setting quality standards for many commercial and military engines. Kaydon lift seal designs provide .Container Closure Integrity Test Using Frequency Modulation Spectroscopy Headspace Analysis with Carbon Dioxide as a Tracer Gas PDA J Pharm Sci Technol. 2021 Mar-Apr . (2, 5, and 10 μm nominal diameter) and tungsten wires inserted between the stopper and the landing seal of the vial (41, 64, and 80 μm outer diameter). During each test .

Thordon SXL segmented axial and radial seals last longer and reduce life-cycle costs compared to carbon seals. WATER CONDITIONING SYSTEMS For any water-lubricated guide bearing, water flow is critical for flushing abrasives, cooling the bearing, and establishing a . • 48 hour test duration • 1” (25mm) shaft diameter • Rotating speed .T +1.562.906.9300 | F +1.562.906.9308 | [email protected]. 10805 Painter Avenue, Santa Fe Springs, CA 90670 USAContainer Closure Integrity: Regulations, Test Methods, Application Deterministic Test Methods Instructors . transducers and mass flow meter • Test time, target vacuum. Mass Extraction. 29. . carbon dioxide concentration, water vapor pressure and total absolute pressure • Output compared to that of standard gas mixtures • Signal is .Labyrinth seal is a kind of typical mechanical seal, widely used in turbo-machinery. And there are many different type of labyrinth seal, such as see-through labyrinth seal, stepped labyrinth seal, staggered labyrinth seal and so on. HaominYuan(2015) studied the see-through labyrinth seal used in SCO 2 flow in fig.2 both numerically and .

Container Closure Integrity: Regulations, Test Methods,

Container Closure Integrity Test Method Development on Vials Stored at -80°C Using Headspace Carbon Dioxide Analysis March 2022 PDA journal of pharmaceutical science and technology / PDA 76(5 .Container Closure Integrity: Regulations, Test Methods, Application –Regulatory Requirements Instructors Coralie Richard, Ph.D.; Eli Lilly and Company; [email protected] . <1207.3> Package seal quality test technologies (Official date: . Shaft finish, hardness, and material are not critical. The seal can handle a wide variety of fluids, pressures up to 3000 psi, speeds to 50,000 rpm, and temperatures from -425-1200 F. This type of seal has become popular on pumps where leakage is not allowed. Radial lip seals are primarily used to retain lubricants and exclude contaminants.• Faster test speed can raise standard deviation of findings • Test sample outer surface moisture may hamper test performance • Test sample temperature influences gas pressure and moisture readings • Not a direct measure of leakage • Leakage can be calculated by analysis of sample headspace change as a function of time

Designed to resist aging, LINK-SEAL wall penetrating seals provide lasting protection against the entry of water, soil, and backfill material. LINK-SEAL’s hydrostatic sealing system of rubber applies secure, consistent pressure around pipes, ensuring error-proof installation in 75% less time than hand fitting flashings, mastics, or casing boots.

Flowserve's seals product portfolio is one of the most comprehensive in the flow control industry. Explore a wide range of seals today.

This study presents a novel, fast, and nondestructive method for CCI testing that uses carbon dioxide as a tracer gas under effusive pressure conditions and utilizes a tunable diode laser absorption spectroscopy technique that employs frequency modulation to enhance measurement sensitivity. As described in USP <1207>, the container closure integrity (CCI) of .As described in USP Chapter <1207>, the deterministic leak test methods using laser-based gas headspace analysis and helium leakage are those with the highest sensitivities. As stated in the chapter, ″no single package leak test or package seal quality test .

• Test sample ‘master’ plus test fixture(s) employed Master: A no-leak model of the container-closure E.g., ‒ A metal or plastic model of the container-closure ‒ A small set of actual container-closures • Leakage reference standards employed E.g., . Given that the values of total acid number (TAN) and sulfur content of the current HVGO are 1.3 kg (mg KOH per gram of hydrocarbon) and 0.67 wt.% respectively, and the operating temperature exceeds 200°C, the jet flow from the nozzle could negatively impact and contribute to corrosion of the feed piping.

Honeywell Releases Improved #4 Carbon Seal To Address Bi-Modality And Risk Of AFT Sump Failure On The HTF7000 Series Engines April 2021. Honeywell issued Service Bulletin AS907-72-9094 that calls for the replacement of the #4 carbon seal on the HTF7000/AS907 series engines. This SB is an improved #4 carbon seal and impacts the following aircraft.

The sterility of drug products intended for parenteral administration is a critical quality attribute (CQA) because it serves to ensure patient safety, and is thus a key requirement by health authorities. Whilst sterility testing is a probabilistic test, the assurance of sterility is a holistic concept including adequate design of manufacturing facilities, process performance, .

Article on Container Closure Integrity Test Method Development on Vials Stored at -80°C Using Headspace Carbon Dioxide Analysis., published in PDA journal of pharmaceutical science and technology 76 on 2022-01-01 by Ken G Victor+2. Read the article Container Closure Integrity Test Method Development on Vials Stored at -80°C Using Headspace Carbon . prevents sump or dome, making CIP-cleaning more efficient and more reliable. A comprehensive range of valve housings are . • A handy clamp closure system or a few bolts (DN125-150 and 6”) between housing and yoke provides quick and easy access . SPX Flow Technology, Zechenstrasse 49, D-59425 Unna, Germany P: +49 (0) 23 03/ 108-0 F: +49 .

understanding voltage drop test

Container Closure Integrity Test Method Development on Vials

Find out how to watch Deal or No Deal Canada. Stream the latest seasons and episodes, watch trailers, and more for Deal or No Deal Canada at TV Guide.

closure flow test c-sump carbon seal|Container Closure Integrity: Regulations, Test Methods,